As the harsh Midwest winter finally begins to fade, business owners and facility managers often breathe a sigh of relief. But while the snow is melting, your building’s HVAC system is facing one of its most critical moments of the year: The Spring Transition.

Your system has just spent months working overtime to heat your facility. Now, it must immediately pivot to cooling. Without a proper “Spring Start-Up,” you risk putting massive strain on a system that is likely dirty, tired, and unprepared for the first heatwave.

At PBear Maintenance, we have seen too many businesses wait until that first 80-degree day to turn on their A/C, only to find it blowing warm air—or worse, not turning on at all.

Here is the Critical Transition Checklist every commercial facility needs to cover before spring hits full swing.

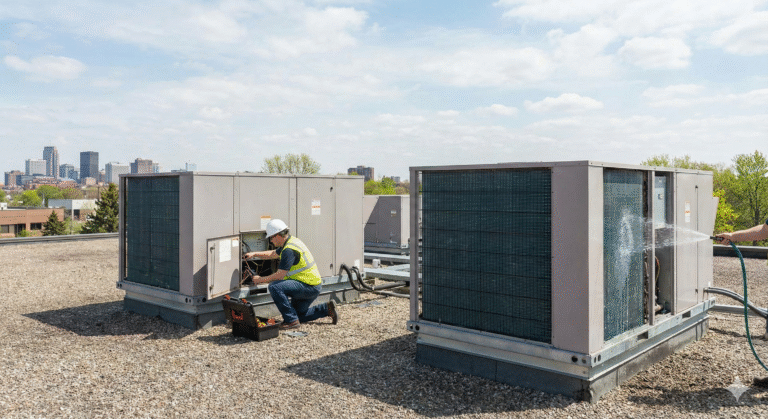

1. The Condenser Coil Deep Clean

During winter, your exterior units are exposed to snow, ice, salt, and debris. This grime builds up on the condenser coils, forming a blanket that suffocates your unit.

-

The Risk: Dirty coils can’t release heat effectively. This forces the compressor to work harder, leading to higher energy bills and premature failure.

-

The Fix: Professional chemical cleaning to remove deep-set grime and restore airflow.

2. Belt and Pulley Inspection

Rubber belts become brittle in freezing temperatures. After a long winter of constant operation, belts often crack, stretch, or loosen.

The Risk: A snapped belt means immediate system downtime. A loose belt causes slipping, which reduces efficiency and damages the pulleys.

The Fix: Inspecting all belts for tension and wear, and replacing them before they snap.

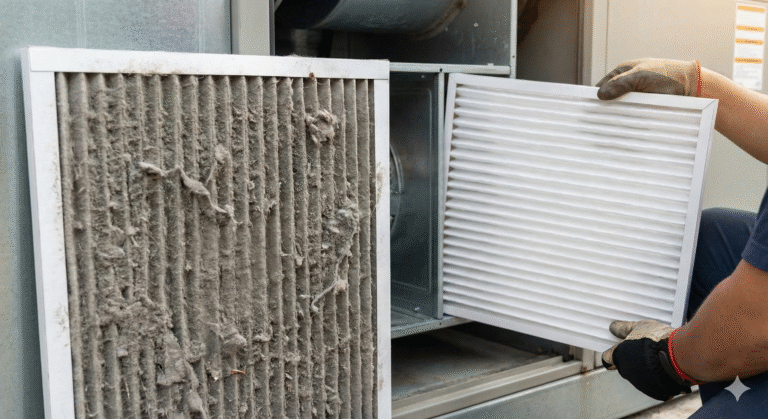

3. Filter Replacement (Don’t Skip This!)

It sounds simple, but it is the #1 cause of HVAC failure. Your filters are likely clogged with winter dust and allergens.

The Risk: Clogged filters restrict airflow. If air can’t move, your evaporator coil can freeze up, potentially destroying your compressor—the most expensive part of your system.

The Fix: Swapping out high-grade commercial filters to ensure clean air and smooth operation.

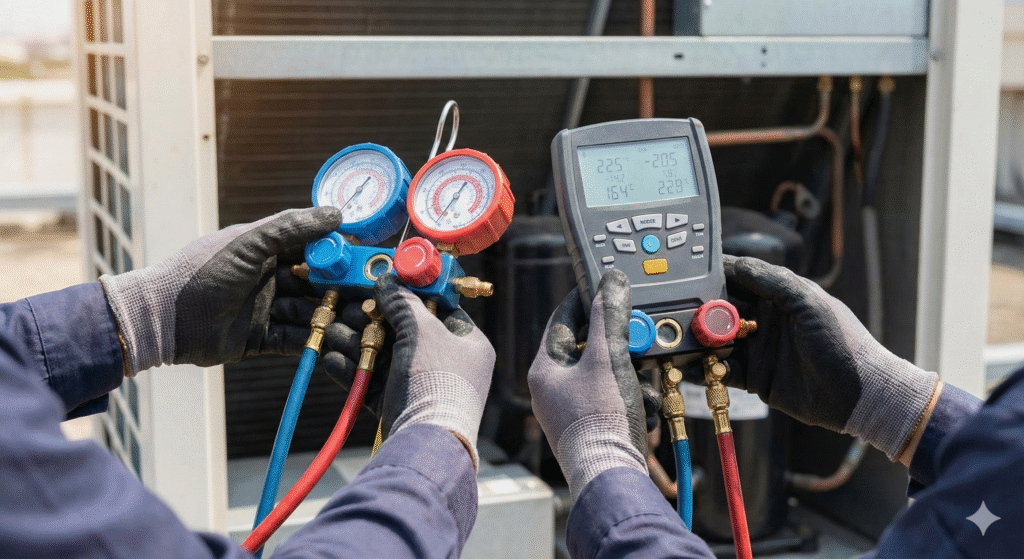

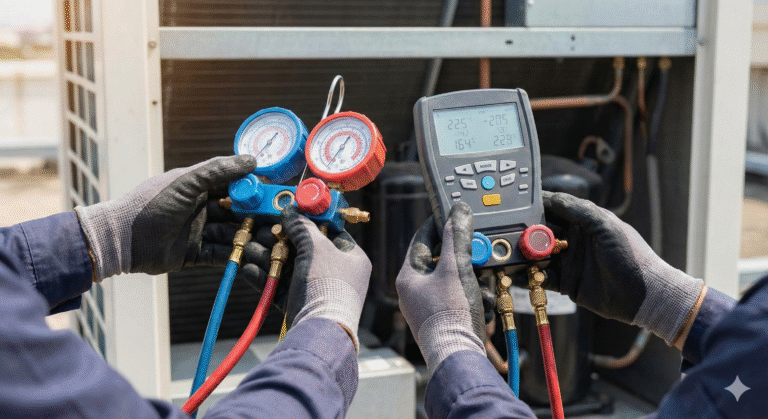

4. Refrigerant Level Check

You don’t need refrigerant in January, so leaks often go unnoticed until spring.

The Risk: Low refrigerant levels (often caused by micro-leaks) mean your system will run non-stop but never actually cool the building. This is a massive energy waster.

The Fix: Pressure testing the lines to ensure you are fully charged and leak-free.

5. Thermostat and Sensor Calibration

Commercial buildings often use complex building automation systems. Sometimes, sensors “drift” or are still programmed for winter setbacks.

The Fix: Calibrating thermostats ensures that when you set it to 72°, it actually stays at 72°.

Why “Reactive” Maintenance is Costing You Money

Many businesses treat HVAC maintenance as an expense to be avoided. In reality, preventative maintenance pays for itself.

Lower Energy Bills: A tuned-up system uses up to 30% less energy than a neglected one.

Longer Lifespan: Regular maintenance can add years to your expensive equipment’s life.

Comfortable Customers: In a restaurant or retail space, a hot, stuffy room drives customers away immediately.

Schedule Your Spring Start-Up Today

Don’t wait for the emergency. Get ahead of the season with PBear Maintenance. We serve businesses across the Midwest, providing certified HVAC-R expertise that keeps your doors open and your customers comfortable.

Ready to get started? 📞 Call us 24/7: (312) 909-1888 📧 Email: support@pbearmaintenance.com 📍 Serving: IL, IN, OH, MI, WI, and beyond.